ABOUT REPRA PRODUCTS

ABOUT REPRA PRODUCTS

Fiberglass reinforcement

Steel has long been indispensable in the entire industry. Steel is also used in various ways for all kinds of constructions in the construction industry. However, steel also has its drawbacks. Notably its susceptibility to corrosion, which affects its lifespan and the durability of the end product.

Therefore, people have long been searching for alternatives. One such example is fiberglass-reinforced plastic fibers.

But an almost unknown form is fiberglass reinforcement

Repra BV therefore introduces for anyone not yet familiar with it the Repra fiberglass reinforcement and its ancillary products.

Over the years, fiberglass-reinforced products have been fully developed and expanded, and our manufacturers hold their own patents and/or certificates (see documents).

For fiberglass reinforcement, no harmonized standard has been established, so it does not qualify for CE marking. Therefore, in 2016, several manufacturers, in collaboration with European institutions, began work on the ETA. Several renowned institutions from Germany, Italy, and France are participating in this project. Repra BV joined this initiative in November 2018.

ETA stands for European Technical Assessment. This European technical assessment provides an independent European procedure for assessing the essential performance characteristics of a construction product. ETA offers manufacturers a voluntary route to CE marking, where the product is not or not fully covered by a harmonized standard (NEN) under the Construction Products Regulation (EU) 305/2011 (CPR). CE marking based on the ETA enables manufacturers to market their products freely on the entire European internal market and allows them to go European with non-standard products or innovative product features.

Already issued Directives and/or Certificates:

Within Europe

- Switzerland: fib Technical Report (Bulletin No. 40)

- Italy: CNR-DT 205/2007

- Germany: DIN 1045-1

- Slovakia: SK 04 – ZSV – 1953

- Poland: AT-15-9516/2015

Outside Europe

- Russia: POCC RU.CM40.H00185 No. 1814748

- Russia: POCC RU.CM40.H00184 No. 1814747

- Russia: GOST31938-2012

- Russia: ISO10406-2008.NEQ

- USA: ACI440.5-08 & ACI 440.6-08

- USA: AASHTO GFRP-1 + various ASTM standards

Properties and Applications of Fiberglass Reinforcement

Composite reinforcement is a product made of fiberglass bonded with thermosetting resins. Its main specialty is the mass index for lightness, calculated using the unit of volume, only 2g/mm3. It is much easier to work with this material and it offers more benefits than working with steel. It also saves costs in transportation and labour.

-

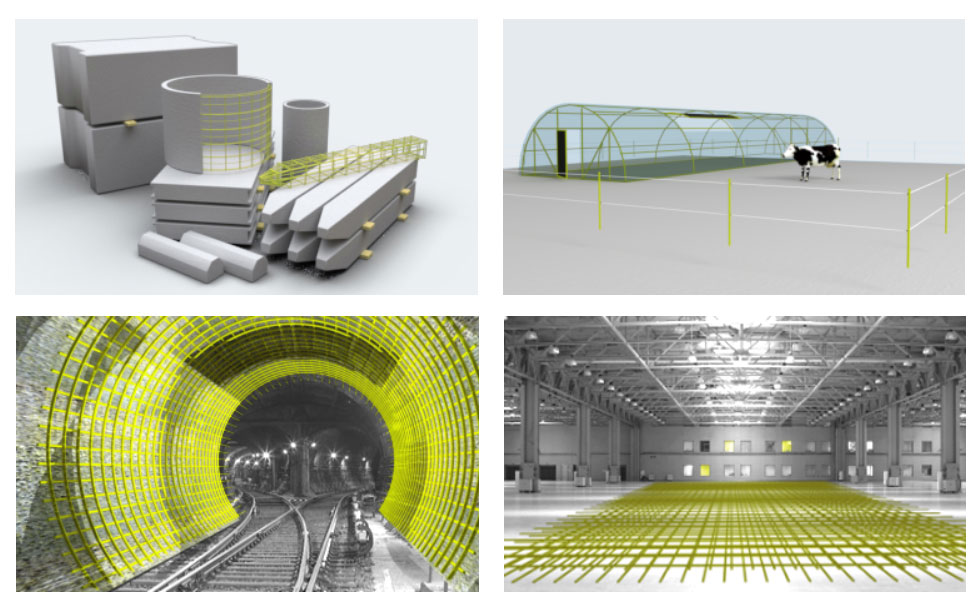

Fiberglass reinforcement is used in both civil construction and industrial structures for reinforcing foundations, floors, and beams.

-

In road construction, composite reinforcement is already widely used for bridge structures and viaducts. An additional major advantage is that it is resistant to chemicals and salts, thus preventing corrosion of the reinforcement.

-

Furthermore, it saves costs in the reinforcement itself as well as in crane costs and concrete mortar.

Also see: